Timing Chain Issues in Renault, Nissan, and Dacia 1.2 TCe Engines: A Common, Recurring Problem

The 1.2 TCe engine, introduced in 2012, is used in several popular models, including the Renault Clio, Captur, and Megane; Nissan Qashqai and Juke; and Dacia Duster and Sandero. Despite being a widely used engine, it is notorious for recurring timing chain failures. These issues persist even when workshops use OEM or aftermarket chain kits.

In previous article, we highlighted how issues like oil dilution and soot buildup, often caused by clogged piston rings, can accelerate engine wear. Now, we turn our focus to another significant issue—the failing timing chains in the Renault 1.2 TCe and Nissan 1.2 DIG-T engines.

Read the article here: https://www.diagnosedan.com/renault-1-2-tce-burned-exhaust-valves-diagnosis/

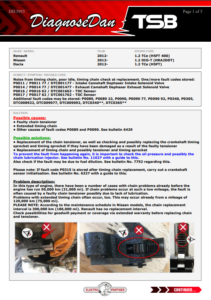

Common Symptoms and Fault Codes:

Drivers often report hearing unusual noises from the timing chain, along with poor idle performance. Diagnostic scans typically reveal the following fault codes:

- P0011 / P0011 77 – Intake Camshaft Dephaser (Intake Solenoid Valve)

- P0014 / P0014 77 – Exhaust Camshaft Dephaser (Exhaust Solenoid Valve)

- P0016 / P0016 62 – TDC Sensor

- P0017 / P0017 62 – TDC Sensor

- Additional codes: P0089, P0089 22, P0090, P0090 77, P0090 92, P0340, P0365, and their variants.

Always Investigate the Cause of a Faulty Timing Chain

It’s crucial to not only replace the timing chain but also investigate the root cause of its failure. One of the most critical checks before installing a new chain kit is assessing both oil pressure and oil quality. These factors often contribute to chain failure and need to be addressed to prevent future issues.

Measuring Oil Pressure

A failing timing chain is often a symptom of an underlying engine issue, such as poor oil pressure or degraded oil quality. To ensure accurate diagnostics, the oil pressure should always be measured when the engine oil is hot, typically above 80°C, when the oil is at its thinnest.

- Remove the oil pressure switch, and fit the oil pressure gauge

- Start the engine and read out the oil pressure

- Compare the measured values with the below data

Consider Oil Dilution

Another common cause of timing chain failure, especially in many direct injection petrol engines, is oil dilution. This occurs when fuel mixes with the engine oil, reducing its lubricating properties and accelerating wear on critical components like the timing chain.

We discussed this issue in detail in DDTSB No. 7280, which includes a video explanation. You can watch the video here: https://youtu.be/YQovbK972qo?si=G2XQyGidQm8rbeR3

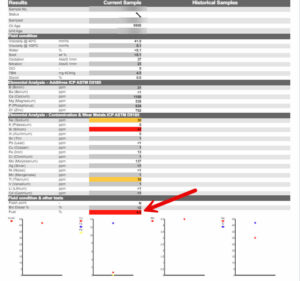

Example of Oil Dilution:

Below is an example of an oil test revealing 4.8% fuel dilution, which is excessively high. Addressing this issue is essential to prevent premature wear and potential failure of the timing chain, ensuring a lasting repair and avoiding repeat visits to the workshop.

Commonly Overlooked Cause of a Worn Timing Chain in the Renault 1.2 TCe Engine

Many modern engines, including the Renault 1.2 TCe, use variable oil pressure systems. This can result in intermittent oil pressure issues, particularly when the engine oil is heavily contaminated with soot.

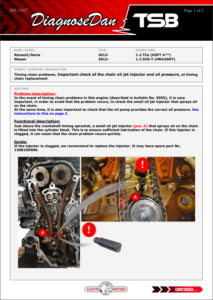

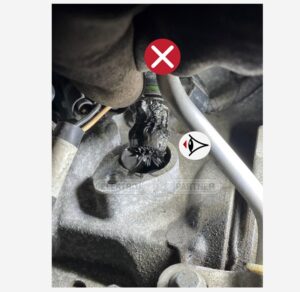

A critical component that is often overlooked by workshops is the oil jet responsible for lubricating the timing chain. This oil jet is highly susceptible to clogging due to soot contamination. If the oil jet becomes blocked, the timing chain won’t receive sufficient lubrication, leading to premature wear and failure.

To avoid future issues, it’s important to thoroughly inspect the oil channels and the condition of the oil jet. If there’s any doubt about its functionality, it’s best to replace it. Given how fragile this system is, especially in relation to oil contamination, it’s essential to emphasize the importance of regular oil changes and, in some cases, using an oil flush to clear any debris.

Showing a picture of the clogged oil jet to your customer can help explain why regular maintenance is so critical. This visual aid could be an effective way to encourage them to stick to their oil change intervals and prevent future timing chain failures.

Diagnosing the Timing Chain Issue

As always in DDTSB, we aim to provide comprehensive diagnostics by including as many measurements as possible to confirm the fault, identify the cause, and highlight common pitfalls. Accurate diagnostics are key to preventing unnecessary repairs and ensuring that the root cause of the timing chain failure is addressed.

Check for metal shavings on Cam- and Crank sensors

Further confirmation of the fault:

Always replace the timing chain as a kit:

It’s important to note that I refer to a timing chain kit, not just the chain itself. Most part suppliers sell the chain as part of a kit, which includes both the crankshaft and camshaft sprockets—and for good reason. If the old timing chain is worn, it likely caused wear on the teeth of the crankshaft and camshaft sprockets as well.

Installing a new timing chain on worn sprockets will result in poor contact between the chain and the sprocket teeth. Worn sprockets often have rounded or smoother teeth, reducing the effective surface area that engages with the chain. This compromised contact can lead to issues such as:

- Slippage

- Misalignment

- Uneven wear

Ultimately, this will shorten the lifespan of the new timing chain, potentially causing premature failure. To ensure a proper fit and long-lasting repair, always replace the timing chain along with the crankshaft and camshaft sprockets as part of a complete kit.

Boost your workshop’s efficiency with DDTSB. Access a vast database of thousands of exclusive aftermarket TSBs to enhance diagnostic precision, save time, and get the repair right the first time. DDTSB: Your investment in faster solutions and higher profitability. Time is money—save both with DDTSB