Chain Stretch, Soot, and Burned Exhaust Valves: Exploring the Common Issues of the Renault 1.2 TCe Engine

In this article we will focus on the problems with 1.2 TCe burned exhaust valve.

Symptoms of Renault 1.2 TCe Engine Issues

The Nissan/Renault 1.2 TCe engine, found in vehicles like the Dacia Dokker, frequently presents a variety of engine symptoms, including the notorious burned exhaust valve, that challenge even skilled technicians. Engine symptoms like chain stretch, soot in the intake, camshaft wear, stuck piston rings, and especially the burned exhaust valve in the Renault 1.2 TCe engine, each present their unique challenges. Additionally, these symptoms can also share common issues, such as carbon deposits on the oil rings. Addressing these symptoms isn’t just about providing a quick fix; it’s about understanding the root causes and offering a lasting solution.

In this deep dive, we’ll focus on a Dacia Dokker, powered by the Renault 1.2 TCe engine, with a total mileage of 64,000 km, which has been diligently maintained yet has fallen victim to one of the most notorious issues of this engine: a burned exhaust valve on cylinder 3. While we’re well-acquainted with the myriad of issues this engine can present, our spotlight in this case study will be on this particular valve issue.

Driving Profile: Predominantly used for short trips, this vehicle has an average annual mileage of 9,000 km.

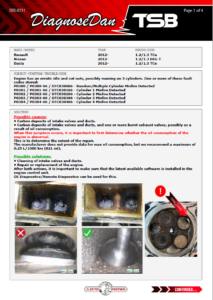

A Word to Technicians: Technicians should always remember, when diagnosing the Renault 1.2 TCe engine symptoms, it’s crucial to first check if the engine’s oil consumption is abnormal. This helps determine the extent of the repair needed. While the manufacturer remains silent on maximum oil consumption figures, our recommendation stands at a maximum of 0.25 L/1000 km (621 mi).

Symptoms in general when this problem occur:

The engine displays a slightly rough idle, which might not immediately raise alarms given its subtle nature. There might be occasional cut-outs, and in some cases, the engine might seem to be running on just three cylinders. However, it’s worth noting that even with a burned valve, the engine can compensate considerably. This adaptability can mask the severity of the issue, leading one to overlook a significant fault like a burned valve. Diagnostic scans could reveal one or more of the following fault codes:

- P0300 / P0300-66 / DTC030066 – Random/Multiple Cylinder Misfire Detected

- P0301 / P0301-66 / DTC030166 – Cylinder 1 Misfire Detected

- P0302 / P0302-66 / DTC030266 – Cylinder 2 Misfire Detected

- P0303 / P0303-66 / DTC030366 – Cylinder 3 Misfire Detected

- P0304 / P0304-66 / DTC030466 – Cylinder 4 Misfire Detected

Problems with soot

Direct injection engines, especially the Renault 1.2 TCe variant, have been noted for accumulating carbon deposits at surprisingly low mileages,

sometimes as early as 30,000 km (18,600 mi). The primary culprits behind this issue are twofold: the inherent design of the engine and the conditions under which it operates.

In these engines, petrol is directly injected into the combustion chamber. This bypasses the intake valves, meaning that the petrol doesn’t assist in keeping them clean as it does in traditional engines. The air that circulates past these intake valves is a mix of fresh air, vapors from the crankcase vent, and exhaust gases from the EGR system. This combination, especially when combined with certain driving conditions, creates a conducive environment for carbon deposits to form on the intake valves.

Burned Exhaust Valve in Dacia Dokker 1.2 TCe

In situations like these, it’s all too easy for a workshop to provide a quick quote to the customer, focusing solely on replacing or repairing the cylinder

head and valve. Such an approach, while addressing the immediate issue, often overlooks the underlying cause. Fortunately, this workshop chose a

different path. Instead of opting for a quick fix, they dedicated time to thoroughly investigate the root of the problem, ensuring not just a repair, but a solution that addresses the core issue.

Spark Plugs: The Silent Indicators of Engine Health

While scan tools provide valuable insights, spark plugs often reveal more about an engine’s condition than any digital readout. A visual inspection of these components should always be the primary health check, even for newer vehicles. Their condition can offer a direct window into the engine’s

overall health and performance.

A damaged porcelain insulator on a spark plug can be a telltale sign of underlying engine issues. But what leads to this damage? Several factors can contribute:

- Detonation or Pre-ignition: This is a common culprit. When the air-fuel mixture in the cylinders is detonated prematurely by the heat of compression rather than by the spark from the spark plug, it can cause a sharp rise in pressure, damaging the spark plug’s porcelain.

- Foreign Debris: Small particles or contaminants inside the combustion chamber can get trapped between the porcelain and the piston or cylinder head, causing the porcelain to crack or chip.

- Improper Installation: Over-tightening or cross-threading during spark plug installation can lead to stress fractures in the porcelain.

- Thermal Shock: Rapid temperature changes in the combustion chamber can cause the porcelain to crack.

- Poor Quality Fuel: Low-quality or contaminated fuel can lead to incomplete combustion, causing hot spots that can damage the porcelain.

- Incorrect Spark Plug Heat Range: Using a spark plug with a heat range that’s not suited for the engine can result in overheating or pre-ignition, both of which can harm the porcelain.

Given the known history of the car, we can confidently rule out issues related to foreign debris, improper installation, poor quality fuel, and incorrect spark plug heat range. This narrows down our focus and emphasizes the importance of understanding the vehicle’s background when diagnosing problems. Addressing the root cause of the damage, not just replacing the spark plug, is crucial for the engine’s longevity and optimal performance.

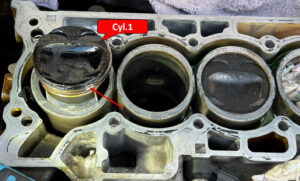

Cylinder Head Inspection Reveals Combustion Issues on cyl. 2 & 3

Upon visually inspecting the cylinder head, it’s evident that there’s a combustion or temperature irregularity in cylinders 2 and 3. This observation aligns with the damaged porcelain on the spark plugs and further underscores the importance of a comprehensive diagnostic approach. Identifying such discrepancies in the combustion process is crucial, as it can lead to a range of engine problems if left unaddressed.

Oil Consumption in 1.2 TCe Engines: A Leading Cause of Burned Exhaust Valve Issues

Consistent oil consumption in engines like these isn’t just a minor inconvenience; it’s a significant concern that can lead to more severe problems. When an engine consumes oil, the carbon deposits tend to be much more pronounced. This heightened accumulation increases the risk of one or more exhaust valves burning out.

The presence of oil in the combustion chamber can disrupt the combustion process, leading to delayed and inefficient burning. This delay results in elevated combustion temperatures. Furthermore, the delayed combustion process creates a situation where the exhaust valves start opening before combustion is fully complete, generating excess heat that can lead to the exhaust valves burning or leaking.

From the images, one could easily assume that this engine was guzzling a significant amount of oil. However, in reality, its consumption was relatively modest at just 0.5L per 100 km.

Adding oil into the combustion chamber effectively acts like reducing the fuel’s octane rating. This slows down the combustion process, leading to a delay in the burn cycle. As a result, the engine might experience knocking or pinging, which are audible signs of pre-ignition. Over time, this delayed combustion can cause increased stress on engine components, potentially leading to premature wear and damage. Moreover, the altered combustion dynamics can result in higher combustion temperatures, which further elevates the risk of damaging critical components like the exhaust valves.

Inspecting the Vital Piston Rings: A Simple Test with the Cylinder Head Removed

With the cylinder head already removed, it provides an opportune moment to inspect the piston rings, especially the oil rings. By aligning the pistons and pouring petrol on top, we can easily

assess their integrity. If the petrol remains stationary on the pistons across all cylinders, it indicates that the rings are in good condition and sealing effectively.

In the provided video, with the cylinder head removed, petrol is poured atop the pistons, serving as a straightforward yet effective diagnostic test. The results are telling: while the petrol remains stationary on some pistons, it seeps away on cylinders 2 and 3. This leakage confirms the suspicions raised by the earlier inspections of the spark plugs, valve coloration, and cylinder head discoloration. https://youtu.be/jUOcx5k3yaU

Unexpected Findings: Aligned Ring Gaps on the Pistons

Upon removing the pistons, an unexpected observation was made: the ring gaps on the piston rings were perfectly aligned. Intriguingly, this alignment was not just present on the problematic

cylinders 2 and 3, but also on cylinder 1, which had shown no leakage in the petrol test. Furthermore, cylinders 1 and 4 had previously demonstrated good compression before disassembly.

Given that the engine had never been taken apart, not even under warranty, this alignment was surprising. While it’s not uncommon for piston rings to rotate and then halt when the gaps align, it’s typically not a desired or intentional configuration. However, in this engine’s case, the aligned ring gaps, though unexpected, were not the root cause of the issues being faced. This discovery underscores the complexity of engine diagnostics and the importance of not jumping to conclusions based on singular observations.

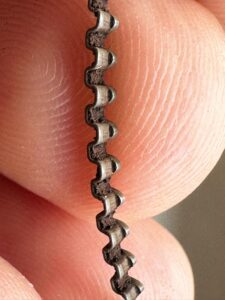

Soot on the Oil Ring Identified as the Culprit

The mystery behind the combustion issues and oil consumption has been unraveled. Upon closer inspection, a significant accumulation of soot was found on the oil ring. The provided images vividly highlight this soot buildup, pinpointing it as the primary cause of the engine’s troubles. Such a buildup can impede the oil ring’s function, leading to both combustion inefficiencies and increased oil consumption.

Thorough Inspection Reveals No Wear on Piston Rings and Bearings

After identifying the soot buildup on the oil ring, the technician took the next logical step: cleaning and measuring the piston rings. The results were reassuring. Despite the issues faced by the engine, the piston rings showed no signs of wear, indicating they were still in good condition.

Furthermore, the bearings on the connecting rod were also inspected and measured. They too were found to be in pristine condition, with no signs of wear or damage. This assessment confirms that the engine did not suffer from insufficient lubrication.

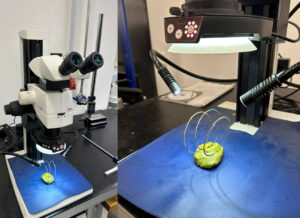

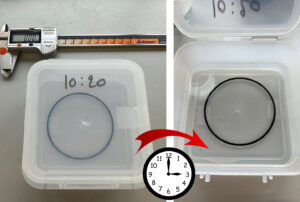

Petrol’s Effect on Soot: An Investigative Experiment

In the quest for deeper understanding, the technician embarked on an experiment to determine if petrol could dissolve the soot accumulated on the oil ring. The oil ring, laden with soot, was

placed in a sealed container filled with petrol and left undisturbed for several hours.

The results were conclusive: the petrol had no effect on the soot. It remained firmly adhered to the oil ring, proving that petrol does not possess the capability to dissolve soot on oil rings. This experiment not only provided valuable insights into the nature of soot buildup but also emphasized the challenges in addressing such issues. https://youtu.be/lOo1YmuPBoU

Handling New Oil Rings: A Word of Caution

When receiving new oil rings, it’s essential to note that they often come in delicate packaging. Given their precision design and the critical role they play in engine performance, it’s imperative to inspect them thoroughly upon arrival. Ensure there are no damages, deformities, or any signs of mishandling.

Almost a Burned Exhaust Valve in Cylinder 2

The exhaust valve seat in cylinder 2 is uniformly blackened, indicating that the valve had inconsistent contact with the cylinder head. This suboptimal contact impedes the efficient transfer of heat from the exhaust valve to the cylinder head. Such heat transfer is crucial for maintaining the valve’s integrity, and any hindrance can lead to the valve burning over time.

What Would Have Happened If We Had Only Repaired the Burned Exhaust Valve or Cylinder Head?

Merely addressing the exhaust valve or the cylinder head without delving deeper into the root cause would have been a temporary solution. It’s akin to placing a band-aid on a wound without treating the underlying infection.

Side Note: Importance of Testing Injectors and Monitoring Spark Plugs

It’s crucial to also test the injectors when undertaking a repair like this, as they play a vital role in the combustion process. Additionally, the workshop should keep an eye on the color of the spark plugs during future maintenance checks. These steps ensure a more comprehensive and long-lasting solution.

Burned exhaust valve on Renault 1.2 TCe

The primary culprit behind the burned exhaust valve in the Renault 1.2 TCe engine is the oil consumption, exacerbated by the oil rings being clogged with carbon deposits or soot. These deposits prevent the rings from working correctly, leading to increased oil consumption. When oil enters the combustion chamber, it disrupts the combustion process, causing delayed and inefficient burning. This delay results in elevated combustion temperatures, which can cause the exhaust valves to burn or leak.

By only repairing or replacing the damaged exhaust valve or cylinder head, we would be addressing the symptom, not the disease. The engine would likely run smoothly for a while, but as oil continues to seep into the combustion chamber due to the damaged oil rings, the same issue would resurface. The exhaust valve would once again be exposed to higher temperatures, leading to another potential burnout.

In essence, without addressing the root cause – the oil rings clogged with soot – the problem would recur, leading to repeated repairs, increased costs, and prolonged vehicle downtime. It’s imperative to understand the interconnectedness of engine components and the domino effect one issue can have on the entire system. Fixing the immediate problem without understanding its origin is a short-sighted approach that can lead to more significant challenges down the road.

So, Who is to Blame for All These Problems?

Diving into the complexities of automotive engineering, it’s evident that the issues with the Renault-Nissan H engine stem from a combination of

factors, each adding its layer of intricacy.

Engineers face a multitude of constraints. With every transition in the Euro norm, such as moving from Euro 5 to Euro 6, the challenges amplify. They’re not only addressing technical challenges but also adapting to changing regulations. Materials and additives previously used in engine design are now off the table due to environmental concerns, pushing engineers to find new solutions.

Then there’s the evolution of oil and fuel, introducing another variable. On top of that, there’s the ever-growing demand for performance. Consumers want more power from their vehicles, yet there’s a consistent push to reduce emissions, all while keeping prices reasonable.

The way a car is used also plays a significant part. Even with the best parts, oil, and fuel, driving behavior can significantly impact an engine. Consider this: here’s a video illustrating the time it takes for an engine to reach its optimal temperature. Imagine that engine in a cold climate, with a driver who starts the car and lets it idle before each short journey. This routine, over time, can lead to issues, regardless of the car’s maintenance.

However, as technicians, we can make a positive impact. By selecting high-quality parts and oils, guiding customers on better driving habits, and suggesting regular oil changes (either annually or every 10,000 to 15,000 km), we can help ensure longer engine life, even in challenging conditions.

Downsized engine comparison: Dacia Dokker’s 1.2 TCe vs. Mazda MX-3 V6

Comparison:

In the realm of automotive evolution, the comparison between the Dacia Dokker’s 1.2 TCe engine and the 1990s Mazda MX-3 V6 is a testament to how far engine technology has come.

- Dacia Dokker with 1.2 TCe Engine (4 cyl.):

- Mazda MX-3 V6 (1992-1996):

- Engine Size: 1.8-liter V6

- Horsepower: 130 hp

- Euro Norm: Euro 1 or Euro 2

Despite being significantly smaller in size, the Dacia Dokker’s 1.2 TCe engine matches the horsepower of the larger 1.8-liter V6 of the Mazda MX-3. More impressively, while delivering the same power, the Dokker’s engine adheres to the much stricter Euro 6 emission standard, highlighting the efficiency and environmental advancements of modern downsized engines compared to their older counterparts.

Video of the engine features

The pictures and investigation to this article was kindly provided by Christophe Veriter (BE)

Staying Ahead of the Curve: Navigating Unknown Engine Challenges with DDTSB

Facing unfamiliar engines? DDTSB offers comprehensive solutions, pinpointing root causes. Our platform alerts workshops about delicate engines, ensuring you’re prepared. Plus, critical maintenance bulletins are prioritized, keeping you informed. With DDTSB, you can confidently tackle any engine challenge, even those you’ve never encountered before.

Wil u meer Bulleting lezen en toegang hebben tot duizenden unieke aftermarket Tsb's?

Ga naar WWW.DDTSB.COM

Relevant links:

https://autospruce.com/1-2-dig-s-hr12ddr-engine-specs-problems-reliability/